BLOG

BLOG

Controlled annealing of plastic parts

Modern plastics are true high-tech products that replace traditional materials in more and more areas.

Keep reading

Did you reduce production downtime and costs while increasing safety?

Maintenance, whether corrective or preventive, usually causes costs related to production stops, the intervention of electrical technicians and the deterioration of electrical equipment.

Keep reading

Next level: Automation in machine tools using mobile robots

Small quantities, great complexity and all this as quickly as possible. The individual wishes of each client pose challenges to industrial companies, to which is added a shortage of specialists and the increase in prices in the matter and services.

Keep reading

Intelligent components for machine optimisation

The goal of Industry 4.0 is above all to achieve, with the support of digital advances and automation, a high-performance factory and production type, adaptable to changing market demands. This includes many technologies and, as centerpieces, what are known as intelligent components.

Keep reading

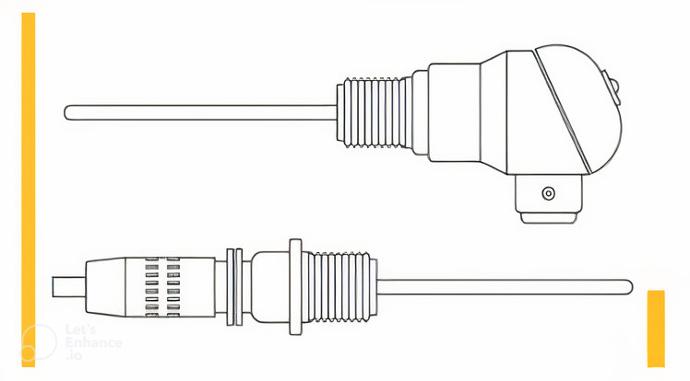

What is an RTD?

Temperature measurement in machines and other industrial processes is one of the key control variables used to ensure the quality of products manufactured in different segments of the industry..

Keep reading

Motion Control: Benefits in Industry 4.0

Technology is often associated with the pursuit of excellence. The improvement of products and services, the reduction of costs and the optimization of times are some of the reasons that explain the reason for the existence of new types of systems such as Motion Control in the industry.

Interoperability: the cornerstone of an electrified future

The electric revolution is here. That means energy systems must be more flexible to maintain energy, manage costs and reduce carbon footprint. And getting there requires elements of our energy infrastructure to work together: at home, at work, and in our communities.